The Stirling engine: A forgotten invention with renewable potential.

The Stirling engine was patented by Robert Stirling in 1816. It’s a type of engine that can use renewable energy. It works by expanding and contracting air or gas, turning heat into mechanical work.

Anúncios

This engine can run on any heat source. It’s great for making sustainable power from solar, geothermal, and nuclear energy.

Even though it’s old, the Stirling engine is still important for renewable energy. This article will look into its history, how it works, its benefits, and its uses today. We’ll see how it can help with renewable energy projects.

What Is a Stirling Engine and How Does It Work?

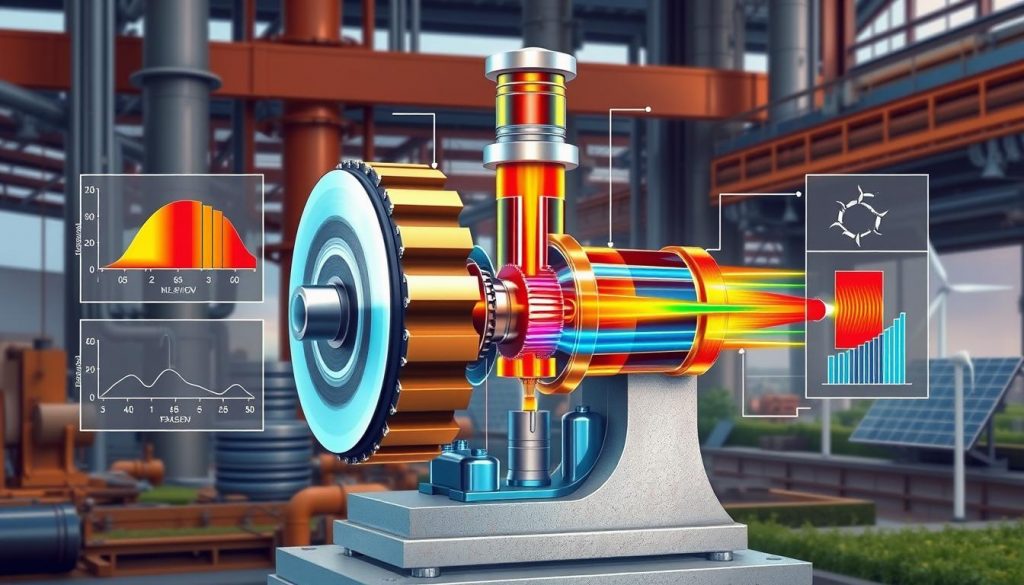

The Stirling engine is a heat engine that uses a closed-cycle regenerative principle. It employs a permanent gaseous working fluid that is heated and cooled. This process produces mechanical work.

This engine is based on the Stirling cycle. It involves the expansion and contraction of a working fluid, like air or helium. This action generates mechanical work.

Anúncios

The Stirling engine has a cylinder, a piston, and a displacer. Together, they convert heat energy into mechanical energy. Its basic principle is simple yet efficient, making it appealing for many uses.

Some key features of the Stirling engine include:

- No valves or timing train, distinguishing it from other engine types

- A fixed amount of gas sealed within the engine

- The pressure of the gas increases when the temperature of the gas is raised

The Stirling cycle has four key phases. The first phase is crucial for producing power. In this phase, the heated gas’s increased pressure boosts power output.

The use of a regenerator in a two-piston Stirling engine can also increase power output. It does this by temporarily storing heat.

The Stirling engine was invented by Robert Stirling in 1816. Since then, it has seen many improvements. These advancements have significantly increased its power output by pressurizing the working fluid.

Today, the Stirling engine is seen as a promising technology for renewable energy. Its high efficiency and low emissions make it an attractive option.

The Fascinating History Behind the Stirling Engine

The history of Stirling engine is rich and interesting, starting in the early 19th century. Robert Stirling, a Scottish clergyman, patented the Stirling engine in 1816. It was first used to pump water in a quarry in 1818. This was the start of the early development of the Stirling engine, which has been key in renewable energy.

Some important moments in the history of Stirling engine are:

- 1816: Robert Stirling patents the Stirling engine

- 1818: The Stirling engine is first used to pump water in a quarry

- 1951: Phillips develops a Stirling generator capable of generating electrical power

Today, the Stirling engine is known for its high thermal efficiency. This makes it great for many uses, like renewable energy and cooling systems.

| Year | Event | Description |

|---|---|---|

| 1816 | Patent filed | Robert Stirling patents the Stirling engine |

| 1818 | First use | The Stirling engine is first used to pump water in a quarry |

| 1951 | Stirling generator | Phillips develops a Stirling generator capable of generating electrical power |

Robert Stirling’s legacy and the history of Stirling engine keep inspiring new ideas in renewable energy. The Stirling engine is still seen as a promising technology for a green future.

Understanding the Science of Thermal Efficiency

The Stirling engine’s thermal efficiency is key to its function. It uses heat exchangers to reach high efficiency. The regenerator, a vital part, stores heat temporarily. This helps the engine keep heat and boost its efficiency.

Several factors affect the Stirling engine’s thermal efficiency. These include:

- Larger temperature differences between the hot and cold ends of the engine

- The type of working gas, such as helium or hydrogen

- Heat transfer losses between the heat source and heater, and from the cooler to the heat sink

- Friction within the engine

Theoretical Stirling engines could hit 100% efficiency if all losses were gone. But, real engines can get up to 50% efficiency, similar to diesel engines. Real-life Stirling engines always fall short of 100% due to heat conduction, friction, and gas imperfections.

Grasping the science behind the Stirling engine’s thermal efficiency is vital. It shows its potential as a green power source. By improving heat exchanger design and cutting losses, Stirling engines can get closer to 100% efficiency. This makes them a strong contender for renewable energy.

| Engine Type | Thermal Efficiency | Power Output |

|---|---|---|

| MOD II Stirling engine | 38.5% | 83.5 horsepower (hp) |

Advantages and Limitations of Stirling Engine Technology

The Stirling engine has many advantages. It is very efficient, produces low emissions, and is quiet. This makes it great for green energy. Compared to other engines, it can reach the highest efficiency possible.

Some key benefits include:

- High efficiency, with some solar plants using Stirling engines reaching over 20% efficiency

- Low emissions, making it cleaner than traditional engines

- Quiet operation, reducing noise by 10-20 dB

But, the Stirling engine also has some limitations. It is expensive and complex. The cost is 2-3 times more than a similar engine, mainly because of the high-temperature materials needed.

It also takes longer to start up, 2-5 times longer than most engines. Despite these challenges, the Stirling engine is still a strong choice for green energy. Its advantages stand out when compared to other engines.

In comparison to other engines, the Stirling engine is much more efficient. It beats the efficiency of gasoline or diesel engines. While it has its drawbacks, its benefits make it a good choice for those seeking efficient, green power.

Modern Applications in Renewable Energy

The Stirling engine has many uses today, especially in renewable energy systems. It’s great for making electricity from solar power.

It’s used to power homes and research stations. For example, homes in Las Vegas and parts of the Netherlands use Stirling engines. This shows how useful they are today.

Stirling engines are good for making solar power because they can use different heat sources. This includes renewable energy like solar and heat from plants.

- Powering cordless hair dryers

- Exploration submarines

- Military subs

- Residential power generation

- Research stations in Antarctica

These examples show how Stirling engines are used in many areas. They help make our energy future more sustainable.

| Application | Description |

|---|---|

| Concentrated Solar Power | Generating electricity from solar energy |

| Residential Power Generation | Providing power to homes and residential areas |

| Research Stations | Powering research stations in remote locations |

Comparing Stirling Engines to Other Power Generation Methods

The Stirling engine is known for its efficiency and cost-effectiveness. It outshines other engines in these areas. This makes it a top choice for green energy.

Stirling engines are great at turning sunlight into electricity. They can do this with up to 31% efficiency. This is better than parabolic trough systems at 16% and photovoltaic panels at 14-18%.

Stirling engines are also cost-effective. They need little maintenance and can run for thousands of hours without losing power. They can be made in various sizes, fitting both small homes and big power plants.

Compared to other engines, Stirling engines have many benefits. They are very efficient, produce less pollution, and are quiet. But, they can be expensive upfront and need special materials that can handle high temperatures.

Environmental Benefits and Sustainability Features

The Stirling engine is good for the environment, making it a green choice for power. It has low emissions and high efficiency. This means it cuts down greenhouse gas emissions, which are a big part of global pollution.

It can use any heat source, making it flexible for green energy. Its high efficiency makes it a better choice than old power methods. For example, using Stirling engine micro-CHP with solar and batteries can cut down pollution by 35% to 100%.

Some big environmental pluses of the Stirling engine are:

- Low greenhouse gas emissions

- High efficiency, leading to less energy use

- Can use any heat source, making it versatile for green energy

- Potential to cut down pollution by 35% to 100% compared to old systems

The Stirling engine is key in fighting climate change and reducing fossil fuel use. Its green benefits and features help us move towards a more sustainable future for power.

Current Research and Development Initiatives

Researchers are working hard to make the Stirling engine better and cheaper. They are focusing on improving its performance and cost. This will help shape the future of Stirling engine technology and its uses.

Some big steps have been made in current research. For example, NASA tested Stirling engines and got up to 28.5 mpg-US. The MOD II project even reached a thermal efficiency of 38.5%, beating modern gasoline engines.

The main areas of focus for current research and development initiatives are:

- Improving thermal efficiency

- Reducing costs and increasing affordability

- Enhancing performance and reliability

As the future of Stirling engine technology grows, we can expect big improvements. This will be thanks to ongoing current research and development initiatives.

| Stirling Engine Type | Power Output | Thermal Efficiency |

|---|---|---|

| γ-type | 9.22 W | 9.8% |

| β-type | 8.7 W | 7.5% |

| α-type | 0.9 W | 1.8% |

Real-World Success Stories and Case Studies

The Stirling engine has found its way into many practical applications. It’s a key player in sustainable power, from solar to waste heat recovery. For example, a study in Bolivia used a biomass Stirling engine with solar power to light up rural areas. You can read about it in the research paper.

Some big wins include the MOD II project, which hit a thermal efficiency of 38.5%. The 1979 AMC Spirit also showed off the engine’s fuel-saving skills, reaching up to 28.5 mpg-US. These stories show the Stirling engine’s potential in real-world use. It’s even powered submarines like the SAGA, proving its worth in air-independent propulsion.

Here are some key benefits of using Stirling engines in case studies:

- High thermal efficiency

- Low emissions

- Flexibility in fuel sources

- Reliability and durability

The Stirling engine has also been used in other practical applications. For example, the ST-5 engine from Stirling Technology Inc. can power a 5 horsepower pump. These success stories and case studies offer a glimpse into the Stirling engine’s future in sustainable energy.

Conclusion: The Future of Stirling Engine Technology

The Stirling engine is becoming more important as we look for clean energy. It’s efficient, produces less pollution, and works well with many heat sources. This makes it a key player in our move towards a greener future.

New materials and better manufacturing have made Stirling engines cheaper. This could lead to more people using them. Experts think the Stirling engine market will grow by about 7% each year until 2030.

The Stirling engine is a bright spot for a cleaner tomorrow. It could help power up to 5 GW of solar energy by 2030. It also saves up to 20% of energy in HVAC systems. This makes it a technology to keep an eye on in the future.