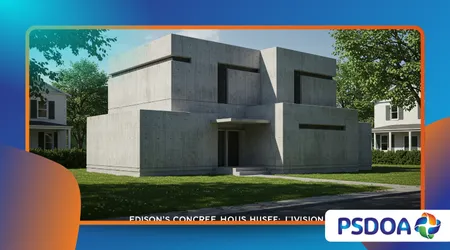

La casa de hormigón de Edison: una visión para viviendas económicas y duraderas

La casa de hormigón de Edison Fue un sueño audaz de un hombre cuyo nombre es sinónimo de innovación. Thomas Edison, el "Mago de Menlo Park", imaginó casas construidas en una sola pieza de hormigón, ofreciendo asequibilidad, durabilidad y seguridad para la clase trabajadora.

Anuncios

A principios del siglo XX, su idea pretendía resolver la crisis de vivienda urbana, prometiendo viviendas ignífugas y a prueba de insectos por tan solo $1.200 (unos $38.000 en dólares de 2025).

Sin embargo, esta ambiciosa iniciativa, patentada en 1917, tropezó con obstáculos prácticos y de percepción pública y cayó en el olvido a pesar de su brillantez vanguardista.

¿Por qué un concepto tan revolucionario no logró arraigarse y qué puede enseñarnos sobre la innovación hoy?

Este artículo profundiza en la historia de La casa de hormigón de Edison, explorando sus orígenes, desafíos, legado y sorprendente relevancia en el panorama inmobiliario de 2025.

Anuncios

La incursión de Edison en el hormigón no fue sólo un capricho: fue un cambio calculado a partir de su negocio de cemento en crisis.

Para 1899, fundó la Edison Portland Cement Company, aprovechando la arena residual de sus fallidas empresas de mineral de hierro. Su visión iba más allá de los simples materiales de construcción: veía el hormigón como un medio para transformar la sociedad.

La idea de una casa de un solo uso cautivó la imaginación, prometiendo albergar a las masas en viviendas resistentes y de bajo costo.

Si bien el concepto fracasó comercialmente, sus ecos resuenan en las tendencias actuales de casas impresas en 3D y construcción modular. Analicemos este invento olvidado, sus audaces objetivos y por qué sigue siendo un fascinante caso de estudio sobre el equilibrio entre visión y practicidad.

El génesis de un sueño concreto

La fascinación de Edison por el hormigón surgió de la necesidad. Su proyecto de molienda de minerales en la década de 1890 le dejó montones de arena residual, que vendía a fabricantes de cemento.

Esto le provocó una revelación: ¿por qué no controlar todo el proceso? En 1899, fundó la Edison Portland Cement Company en Nueva Jersey, donde introdujo innovaciones como hornos rotatorios de 45 metros, los más grandes de su época.

Estos avances convirtieron a su empresa en el quinto mayor productor de cemento para 1910, pero la sobreproducción era inminente. Edison necesitaba un nuevo mercado, y el sector inmobiliario parecía propicio para la disrupción.

La crisis de vivienda urbana de principios del siglo XX impulsó su ambición. Ciudades como Nueva York estaban repletas de barrios marginales, viviendas insalubres y propensas a incendios, donde los trabajadores vivían en la miseria.

Edison vio La casa de hormigón de Edison Como solución: una casa hecha en un solo vertido continuo, incluyendo paredes, pisos, techos e incluso bañeras, todo formado a partir de un único molde.

No se trataba solo de eficiencia, sino de bienestar social. Su objetivo era hacer que las viviendas fueran asequibles para la clase trabajadora, estimando un coste de $1.200 por casa, muy por debajo de los precios de construcción tradicionales.

Su patente de 1917 describió un proceso radical: un molde reutilizable con 2300 piezas de hierro niquelado daría forma a una casa entera de una sola vez. El hormigón fluiría desde un embudo en la azotea, llenando cada rincón en cuestión de horas. ¿El resultado?

++ La historia olvidada de la energía solar en el siglo XIX

Una casa ignífuga, a prueba de insectos y casi indestructible. Edison incluso donó la patente a constructores cualificados, con la esperanza de impulsar una revolución inmobiliaria sin lucro personal. Pero, como veremos, el idealismo por sí solo no pudo superar las barreras prácticas.

La audacia de esta visión fue asombrosa. Imaginen a un escultor creando una estatua, pero en lugar de arcilla, es una casa de dos pisos vertida de una sola vez.

El sueño de Edison no se limitaba a los edificios, sino a reimaginar cómo viviría la sociedad. Sin embargo, la brecha entre el concepto y la ejecución sería su perdición.

El triunfo técnico y sus obstáculos

Técnicamente, La casa de hormigón de Edison Fue una maravilla. El equipo de Edison desarrolló una mezcla de hormigón lo suficientemente fluida como para llenar moldes intrincados, pero lo suficientemente espesa como para mantener su estructura.

En 1910, probó el concepto moldeando un garaje y una cabaña de jardinero en su finca de Glenmont, Nueva Jersey. Estos experimentos funcionaron, demostrando que el método de vertido único era viable.

El proceso implicó ensamblar un molde complejo, verter el hormigón lentamente para evitar la acumulación de presión y retirar el molde después de siete días para revelar una casa terminada.

Sin embargo, los desafíos eran inmensos. El molde en sí mismo era una pesadilla logística, compuesto por 2300 piezas y con un peso de casi medio millón de libras.

Lea también: El Cyclomer: una bicicleta que podría flotar en el agua

Los constructores necesitaban invertir $175.000, aproximadamente $3,5 millones en dólares de 2025, antes de construir una sola casa.

Este costo inicial era prohibitivo, especialmente para un método no probado a gran escala. Comparemos esto con las casas modernas impresas en 3D, donde las impresoras cuestan una fracción de precio y se pueden reutilizar fácilmente.

| Aspecto | La casa de hormigón de Edison | Casa moderna impresa en 3D |

|---|---|---|

| Costo del equipo | $175,000 (1917) | $10.000–$400.000 (2025) |

| Tiempo de construcción | 7 días (más 12 horas de instalación) | 24–48 horas |

| Material | cemento Portland | Hormigón, compuestos |

| Escalabilidad | Limitado por la complejidad del molde | Altamente escalable |

La percepción pública también obstaculizó la adopción. Muchos veían las casas de hormigón como cajas frías y utilitarias, ideales para habitantes de barrios marginales, no para familias con aspiraciones.

La visión de Edison de la elegancia, con paredes de hormigón tintado y accesorios empotrados, no convenció a los escépticos que preferían las casas con estructura de madera. A pesar de estos obstáculos, se construyeron algunas casas, como las de Montclair, Nueva Jersey, y Gary, Indiana, algunas de las cuales aún se mantienen en pie.

El equipo de Edison también tuvo dificultades con la mezcla de hormigón. Debía fluir por todas las grietas sin asentarse, un equilibrio químico que puso a prueba los límites de la ingeniería de la época.

Si bien tuvieron éxito en pruebas a pequeña escala, la ampliación introdujo variables como vertidos irregulares o desalineaciones del molde que podían arruinar una casa entera. Estas proezas técnicas, aunque impresionantes, subrayaron una verdad: la innovación a menudo supera a la practicidad.

Leer más: ¿Por qué dejamos de usar zepelines para viajar?

La magnitud de la ambición de Edison invita a la reflexión. ¿Podría un molde menos complejo haber cambiado el resultado?

Simplificar el diseño podría haber reducido los costos, lo que La casa de hormigón de Edison Más atractivo para los constructores. Sin embargo, el enfoque de todo o nada de Edison, al fundir todo, desde escaleras hasta lavabos, puede haber sido su mayor defecto.

Una visión social adelantada a su tiempo

El objetivo de Edison no era solo técnico; era profundamente humanitario. Él vio La casa de hormigón de Edison como una forma de ayudar a la clase trabajadora, ofreciendo viviendas seguras y asequibles para reemplazar los peligrosos edificios de viviendas.

En 1906, declaró: “Viviré para ver el día en que la casa de un trabajador pueda construirse de hormigón en una semana”. Su filantropía brilló cuando donó la patente, con la esperanza de iniciar un movimiento.

El filántropo Henry Phipps Jr. incluso prometió donar entre 1 y 1 millón de dólares para construir viviendas de hormigón para los pobres de Nueva York, inspirado por la visión de Edison.

Este enfoque social resuena en 2025, ya que la asequibilidad de la vivienda sigue siendo una crisis mundial. Un informe de ONU-Hábitat de 2023 señaló que 1.600 millones de personas viven en viviendas inadecuadas, una cifra que se prevé que aumente.

La idea de Edison de viviendas de bajo costo y producción en masa prefiguró las soluciones actuales de vivienda modular e impresa en 3D, que buscan abordar problemas similares. Empresas como ICON y Apis Cor ahora imprimen casas en cuestión de días, imitando el sueño de Edison, pero con una tecnología más ligera y flexible.

Sin embargo, el idealismo de Edison chocaba con la realidad. El precio de $1,200 era optimista, ya que ignoraba los costos de mano de obra y terreno.

Los constructores se resistieron a la complejidad del molde, y los inquilinos dudaron en aceptar la estética austera del hormigón. Aun así, la visión de la vivienda como un derecho, no un lujo, fue radical para su época. El fracaso de Edison no residió en soñar a lo grande, sino en subestimar la inercia de la tradición.

Consideremos un paralelo moderno: las minicasas. Como La casa de hormigón de EdisonApuntan a la asequibilidad y la eficiencia, pero luchan contra las leyes de zonificación y los prejuicios culturales que favorecen las viviendas más grandes.

El paso en falso de Edison nos enseña que la innovación requiere tanto apoyo social como destreza técnica. Sus casas de hormigón, aunque pocas, son un ejemplo de esta tensión entre visión y aceptación.

El legado y los ecos modernos

Aunque La casa de hormigón de Edison Nunca se ha escalado, pero su legado perdura. Unas pocas casas supervivientes, como las de Phillipsburg, Nueva Jersey, y Gary, Indiana, siguen funcionando, con una durabilidad comprobada durante más de un siglo.

La casa Montclair en 303 North Mountain Avenue, restaurada en 2015, muestra el potencial que Edison vio: una vivienda a prueba de fuego y de bajo mantenimiento que todavía es habitable hoy en día.

Estas reliquias resaltan una estadística clave: las estructuras de hormigón pueden durar más de 100 años con un mantenimiento mínimo, según el Instituto Americano del Hormigón.

El concepto de Edison también anticipó las tendencias de construcción modernas. En 2025, las casas de hormigón impresas en 3D están ganando terreno, con empresas como Mighty Buildings produciendo unidades por menos de $200,000 en cuestión de días.

A diferencia de los moldes rígidos de Edison, estos utilizan brazos robóticos y materiales reciclables, lo que evita sus problemas logísticos. Sin embargo, la idea central de una vivienda duradera y producida en masa se remonta a la visión de Edison.

Su influencia se extiende más allá del sector inmobiliario. La Edison Portland Cement Company suministró hormigón para el Yankee Stadium en 1922, un proyecto que se completó en 284 días utilizando 35.000 yardas cúbicas de hormigón.

Sus paredes resistieron con firmeza durante las renovaciones de 1973, testimonio de las innovaciones materiales de Edison. Esta durabilidad refleja lo que buscaba para las viviendas: estructuras que sobrevivan a sus constructores.

El fracaso de Edison también ofrece una lección sobre el ciclo de vida de la innovación. Como un barco que se bota antes de que su tripulación reciba formación, su idea era técnicamente sólida, pero social y económicamente inexperta.

Los innovadores de hoy pueden aprender de esto: las ideas innovadoras necesitan un andamiaje práctico para triunfar. El sueño de Edison, aunque olvidado, sembró las semillas de las soluciones de vivienda actuales.

El contexto cultural del fracaso

¿Por qué? La casa de hormigón de Edison ¿Fallan cuando su intención era tan noble? La respuesta reside en el contexto cultural de los Estados Unidos de principios del siglo XX. La propiedad de una vivienda estaba ligada a las casas con estructura de madera, consideradas cálidas y personalizables.

El hormigón, en cambio, tenía un aire industrial, incluso institucional. La visión de Edison de paredes tintadas y accesorios empotrados no lograba disipar la percepción de cajas frías y utilitarias. Esta resistencia cultural refleja los debates modernos sobre la arquitectura brutalista, a menudo denostada a pesar de su durabilidad.

La inclinación de Edison por utilizar muebles de hormigón (cajas para fonógrafos, pianos e incluso lápidas) alejó aún más a los consumidores.

Un artículo del New York Times de 1911 se burlaba de la idea de “gatos de cemento que ronroneaban como piedras” bajo las cocinas, lo que ponía de relieve el escepticismo del público.

La gente ansiaba familiaridad, no una reinvención radical. Esta resistencia subraya una verdad intemporal: la innovación debe alinearse con los valores culturales para tener éxito.

Hoy en día, observamos una oposición similar a las casas modulares en algunas comunidades, donde la estética tradicional reina. La historia de Edison nos recuerda que incluso las mejores ideas necesitan un público receptivo.

Sus casas de hormigón, aunque pocas, nos desafían a repensar lo que significa “hogar” en una era de cambio climático y escasez de viviendas.

Conclusión: Una visión que vale la pena revisar

La Casa de Hormigón de Edison fue un paso audaz que se quedó corto, pero dejó una huella imborrable. Su fracaso no se debió a la falta de ingenio, sino a la fricción entre la visión y la realidad. En 2025, mientras lidiamos con las crisis de vivienda y los desafíos climáticos, el sueño de Edison se percibe inquietantemente profético.

Su idea de viviendas duraderas y asequibles se alinea con los objetivos modernos, desde las casas impresas en 3D hasta la planificación urbana sostenible. Al aprender de sus errores, la complejidad y la desconexión cultural, podemos refinar su visión del mundo actual.

¿Y si nos atreviéramos a soñar tan grande como Edison, pero con el sentido práctico que le faltaba? Sus casas de hormigón, aunque olvidadas, nos recuerdan que incluso las ideas fallidas pueden allanar el camino para futuros avances.

Preguntas frecuentes: Desentrañando la Casa de Hormigón de Edison

1. ¿Por qué la Casa de Hormigón de Edison no logró triunfar?

El alto costo de los moldes ($175,000 en 1917) y la percepción pública del hormigón como utilitario disuadieron a constructores y compradores, a pesar de la durabilidad de las casas.

2. ¿Quedan todavía en pie algunas de las casas de hormigón de Edison?

Sí, quedan ejemplares en Montclair y Phillipsburg, Nueva Jersey, y Gary, Indiana, algunos ocupados y en buenas condiciones a partir de 2025.

3. ¿Cómo se relaciona la idea de Edison con la vivienda moderna?

Su concepto de vertido único prefigura las casas impresas en 3D, que utilizan mezclas de hormigón avanzadas y robótica para crear viviendas asequibles y duraderas en cuestión de días.

4. ¿Se benefició Edison de su patente de casa de hormigón?

No, donó la patente a constructores calificados, priorizando el impacto social sobre las ganancias, aunque pocos adoptaron la tecnología.

5. ¿Qué podemos aprender hoy de este invento?

La visión de Edison resalta la necesidad de equilibrar la innovación con la practicidad y la aceptación cultural, una lección para los innovadores en vivienda de 2025.