How We’re Printing Human Organs With Bio-Ink

We’re Printing Human Organs With Bio-Ink to bridge the gap between tragic waiting lists and a future where biological failure is no longer a death sentence.

Anuncios

In early 2026, the intersection of robotics and regenerative medicine has shifted from laboratory experiments to real-world clinical discussions about personalized patient care.

My analysis suggests that we are witnessing the dawn of “Biological Manufacturing,” where living cells serve as the raw material for complex structural engineering.

This technological leap transforms how we perceive the human body, treating diseased tissue not as a permanent loss, but as a replaceable component.

Quick Overview of Bioprinting Progress

- Tecnología: Precision 3D deposition using cellular clusters and hydrogel scaffolds.

- The Medium: Specialized bio-inks derived from the patient’s own adipose or stem cells.

- Current Milestone: Successful printing of vascularized skin grafts and complex cartilage structures.

- The Horizon: Fully functional, transplantable hearts and kidneys tailored to individual genetic profiles.

How does bioprinting technology transform medicine?

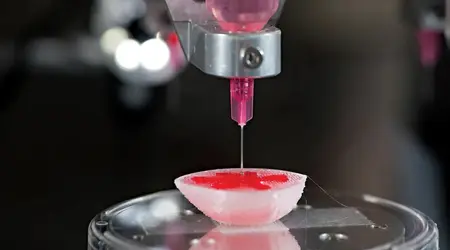

Scientists now use specialized 3D printers to deposit thin layers of living cells, creating structures that mimic the complexity of human tissue.

Anuncios

The process begins with a digital map, where an MRI or CT scan guides the printer nozzle with sub-millimeter precision across a sterile platform.

We’re Printing Human Organs With Bio-Ink by using a delicate balance of temperature and pressure to ensure cell survival during the extrusion phase.

If the pressure remains too high, the mechanical force destroys the cell membranes, rendering the entire biological structure useless for medical implantation.

What is the composition of bio-ink?

Bio-ink typically consists of a cocktail of living cell clusters mixed with a nutrient-rich hydrogel that acts as a temporary biological glue.

This gel provides the necessary structural support while the cells begin to communicate and form the natural extracellular matrix required for tissue stability.

In my view, the gel behaves like a biological scaffolding, allowing the “building” to hold its shape until the resident cells take over.

Once the cells fuse and mature, the hydrogel often dissolves, leaving behind a purely organic structure that the patient’s body can integrate.

++ Cibernética en la naturaleza: bucles de retroalimentación en el reino animal

Why use a patient’s own cells?

Using autologous cells eliminates the risk of organ rejection, which remains the primary hurdle in traditional transplantation surgery today.

By harvesting a patient’s stem cells, doctors ensure that the immune system recognizes the printed organ as “self” rather than a foreign invader.

What many forget to observe is that this personalization reduces the need for lifelong immunosuppressant drugs, which often carry severe side effects.

We’re Printing Human Organs With Bio-Ink specifically to tailor the geometry and biology of the replacement to the unique needs of the recipient.

What are the current challenges in printing whole organs?

Creating a solid block of tissue is relatively simple, but building a functional organ requires a complex network of microscopic blood vessels.

Without a constant supply of oxygen and nutrients, the cells in the center of a printed organ quickly die from metabolic suffocation.

We’re Printing Human Organs With Bio-Ink while simultaneously trying to solve the “vascularization problem” through integrated microfluidic channels that mimic the circulatory system.

This is the ultimate engineering challenge: how do you print a highway system for blood at the same time as the city?

Lea también: Computadoras líquidas: ¿Podemos reemplazar el silicio con lógica fluida?

How do we print blood vessels?

Innovative researchers have developed “sacrificial inks” that hold space for vessels during the printing process but melt away once the tissue stabilizes.

This leaves behind hollow tunnels that can be lined with endothelial cells, eventually allowing blood to flow naturally through the artificial organ.

Minimizing the scale of these vessels is difficult, as capillaries are thinner than a human hair and require extreme precision to replicate.

We’re Printing Human Organs With Bio-Ink using high-resolution laser systems that can trigger cell placement without physical contact, preserving the integrity of fragile biological layers.

Leer más: La dilatación del tiempo en la vida real: ¿qué les sucede a los astronautas?

Why is organ maturation necessary?

A freshly printed heart does not immediately begin to beat; it requires a period of “incubation” in a bioreactor that simulates body conditions.

This environment provides electrical and mechanical stimulation, teaching the cells to work in unison as a functional, rhythmic muscle rather than a static shape.

My recommendation for you is to view the printer as the “assembler” and the bioreactor as the “trainer” of the new organ.

Según un 2025 study published in Nature Biotechnology, tissues matured under mechanical stress showed a 40% increase in structural durability compared to static models.

Why is the ethical debate shifting in 2026?

As the technology advances, we must confront the reality of bio-manufacturing and its implications for human life extension and commercial organ markets.

We’re Printing Human Organs With Bio-Ink at a pace that often outstrips our current legal frameworks regarding biological property and medical equity.

Could we one day print “upgraded” versions of our organs, or will this technology be reserved only for the world’s wealthiest individuals?

I believe we are approaching a societal crossroads where the definition of “natural” health will be challenged by our own manufacturing capabilities.

Who owns the genetic blueprint?

The digital files used to print an organ contain sensitive genetic information that could, in theory, be used to replicate a person’s biology.

Establishing clear ownership rights over these “biological CAD files” is essential to prevent unauthorized use of a patient’s personal cellular identity.

In my analysis, the data is as valuable as the cells themselves, requiring new encryption standards for medical records in the bioprinting age.

We’re Printing Human Organs With Bio-Ink while essentially creating a digital twin of our internal anatomy, which brings massive privacy concerns.

How does bioprinting reduce animal testing?

Pharmaceutical companies are already using printed human liver and skin tissues to test new drugs, drastically reducing the reliance on animal models.

These “organ-on-a-chip” systems provide more accurate data because they utilize human biological responses rather than cross-species approximations that often fail in trials.

This shift not only satisfies ethical concerns but also accelerates the development of life-saving medications by identifying toxicity early in the process.

We’re Printing Human Organs With Bio-Ink to save lives today, even before the first full heart transplant from a printer becomes a common reality.

Medical Bioprinting Comparison Table (2026 Status)

| Organ Type | Current Development Stage | Major Technical Hurdle | Estimated Clinical Use |

| Skin Grafts | Clinical Trials / In Use | Pigmentation & Hair Follicles | Available Now |

| Bladder | Pilot Human Implants | Structural Elasticity | 1-2 Years |

| Liver Patch | Pre-clinical Toxicology | Metabolic Complexity | 3-5 Years |

| Heart | Prototype Maturation | Synchronized Beating | 8-10 Years |

| Kidney | Micro-structural Research | Filtration Networks | 12+ Years |

The evolution of medical manufacturing suggests that We’re Printing Human Organs With Bio-Ink is the most significant achievement of modern biology.

We have moved from simply repairing the body to actively regenerating it using the patient’s own cellular code as the primary blueprint.

This journey from digital imaging to living, breathing tissue represents a triumph of human ingenuity over the limitations of our own mortality.

While the challenge of printing whole, complex organs like the kidney remains daunting, the progress in skin and cartilage is already changing lives.

As we refine our bio-inks and bioreactors, the line between technology and biology will continue to blur.

We are no longer just observers of life’s complexity; we are becoming its master architects, one layer of cells at a time.

Do you believe a printed heart could eventually be superior to the one you were born with, or does that cross a line we aren’t ready for? Share your experience in the comments!

Preguntas frecuentes

Is a bioprinted organ considered a “cyborg” part?

No, because it consists entirely of biological material and the patient’s own cells, making it a natural extension of their body.

How long does it take to print a human organ?

A simple skin graft can take minutes, while a complex scaffold like a heart could take several days of continuous 3D printing.

Will bioprinting make organ donors obsolete?

Eventually, yes, but for the next decade, we will still rely on traditional donors while bioprinting technology scales for complex internal organs.

We’re Printing Human Organs With Bio-Ink, but is it expensive?

Currently, the cost is high due to the specialized cleanrooms and stem cell processing required, but prices are falling as automation increases.

What happens if the bio-ink dries out?

The cells would die instantly. The entire printing process must occur in a highly humidified and temperature-controlled environment to keep the “ink” alive.